How to extend life of diesel engine?

- Home

- How to extend...

How to extend life of diesel engine?

We don't know what automobile brand you have, but we are certain that you want to extend the service life of your vehicle as much as possible. A car is similar to a human body in that everything functions together as the heart beats. The engine is, of course, the heart of the vehicle. Before we can explore how to reduce engine wear, we must first understand how it occurs.

Dmitrii Garkunov's book "Tribotechnic" discusses the wear mechanism of metal surfaces as well as other forms of wear.

Let’s highlight main ones:

- Metal rubbing surface wear — this combination of abrasion and crumpling. Abrasion is the separating or cutting of metal particles followed by removal. Crumpling is the process of modifying the linear dimensions of a component without losing mass owing to flattening.

- At the same time, there are three types of wear processes: friction surface contact, changes in the metal's surface layer, and surface destruction.

There are two types of interaction between surfaces:

- Mechanical – mutual engagement of sliding surfaces and embedding of sliding surfaces.

- Molecular – ssurface adhesion and grasping with breakout. When the oil film is destroyed, it is inescapable.

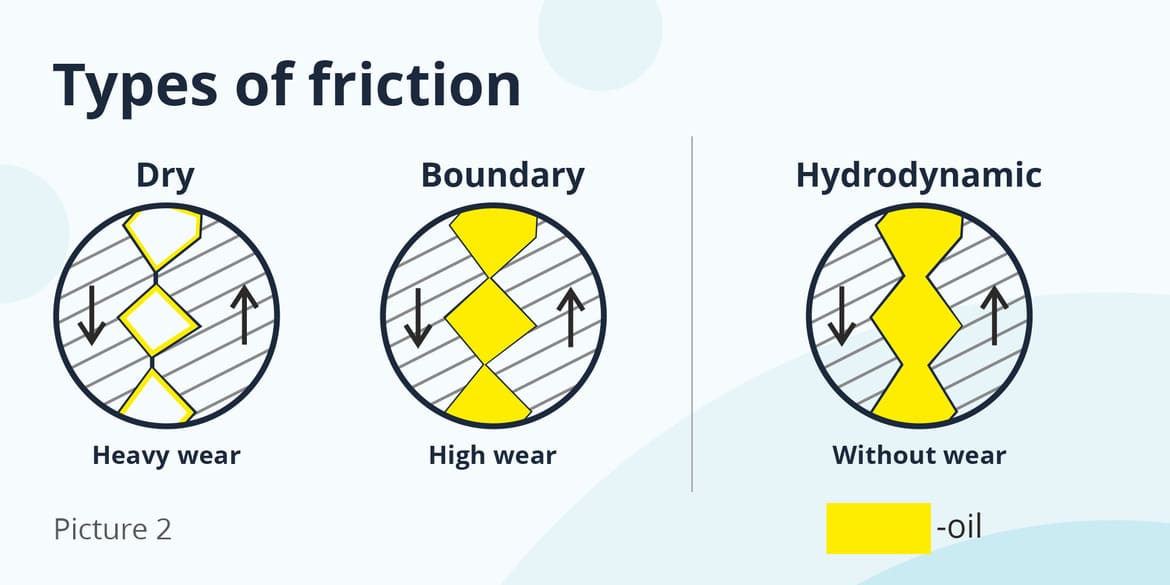

There are 3 types of frictions:

- Dry friction (without lubricity) This causes fast wear and tear.

-

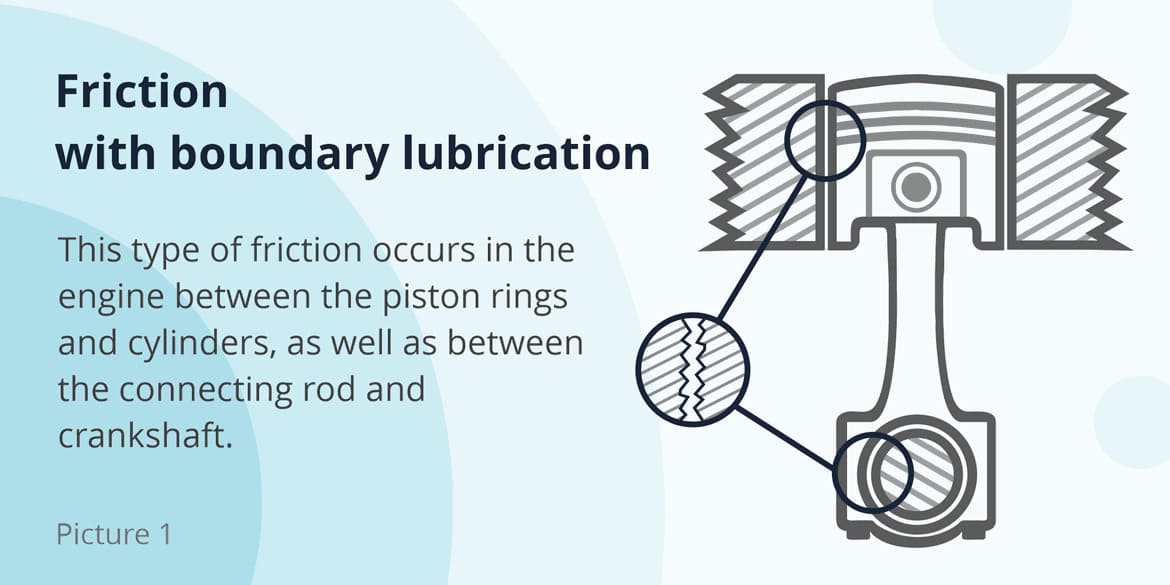

Boundary friction

The oil coating between the components, of course, minimizes friction force and wear on the rubbing surfaces, but it does not fully eliminate it. Why? It's just that it's so little. This form of friction happens between the rings and cylinders of the engine.

-

Hydrodynamic friction

When the oil is supplied under pressure, such friction can occur between the crankshaft or camshaft necks and the liners. Because the rubbing surfaces are totally separated by a layer of grease, they do not wear out.

Of course, friction isn't the only thing that wreaks havoc on an engine's surface. There is also abrasive and hydrogen wear, as well as oxidative and corrosion-mechanical wear. We need to talk about hydrogen wear more. What is going on?

Atomic hydrogen is emitted from any oil or fuel and enters the metal's underlying layer. It transforms into a molecular gas there, producing pressure that destroys the rubbing surface from inside. It eventually turns to powder and is taken away by the oil. Unfortunately, this is a never-ending process.

So, how to protect “heart” of car?

We must state that there is no miracle-advice on how to make the "heart of the automobile" operate for years. On every automotive forum, you may find "home-experts" who will advise you, "Change your oil more often, and you'll have no issues!"

Oil changes, as well as prompt, regular maintenance, are unquestionably crucial. However, as we discovered above, the oil itself frequently contributes to hydrogen wear, implying that they cannot do so alone. Anti-wear compounds were developed specifically for this purpose.

When they are mixed into the fuel, they generate a robust tribological layer on the surface of the working components of various mechanisms, reducing wear and protecting the metal from caustic acids. The film is made up of the byproducts of the additive's mechano-chemical changes on the metal surface. The friction mode determines how it forms. More than ten different approaches are employed in research to evaluate lubricating characteristics based on the coefficient of friction, the average diameter of the wear spot, and the critical load before jamming.

Furthermore, anti-wear additives boost engine operating life, bring fuel performance up to regulatory standards, preserve fuel system parts from corrosion, and, as a consequence, lower the cost of periodic maintenance. The approved lubricant additive has no effect on other diesel fuel indications such as fluidity, color, and so on, and its usage and storage do not necessitate any specific equipment.

Anti-wear additive of new generation:

The wear and tear of fuel equipment parts is a painful problem for diesel engine owners. We investigated this issue thoroughly and created an anti-wear (lubricating) ingredient called "Molecule", which is a combination of fatty carboxylic acids in a hydrocarbon solvent. It is designed specifically for hydrotreated low-sulfur diesel fuels.7

The addition of "Molecule" to the fuel at a concentration of 200 ppm enhances lubricating characteristics by 40-50 percent and reduces the diameter of the wear spot from 550 to 370-330 microns. However, be aware that the use of this addition necessitates a certain temperature regime: for more efficient interaction, both the additive and the fuel must be heated to 40-50 degrees.

Another significant property of all anti-wear additives, including "Molecule," should be mentioned. There is competition for the surface of additives in the presence of other additives in the fuel, such as depressant-dispersing or cetane-increasing additives, whose working concentrations are an order of magnitude greater. Unfortunately, anti-wear is subpar. In this scenario, they should be added to diesel at a higher concentration.

The addition is a genuine, effective technique to reduce wear and tear, allowing your car's heart to perform as long as possible and without interruption!