Antigel Dixon® – dispersant and depressor additive

Complies with EURO-5!

Description

Antigel Dixon® effectively improves the low-temperature properties of diesel fuel (lowers cold filter plugging point and pour point).

Laboratory research

Antigel Dixon® was successfully tested in the laboratory.

The goal of the experiment was to see if adding the addition to diesel fuel reduced the cold filter clogging threshold

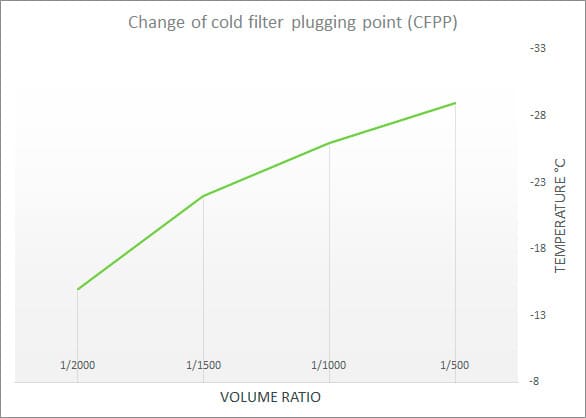

Summer diesel fuel with a CFPP of -7,0 °C was used as the initial sample.

The tests were carried out at a temperature of 22,0 °С, a humidity of 62 % and an atmospheric pressure of 100,6 kPa.

The cold filter plugging point decreased by 10,0 °C from -7,0 °C to -17,0 °C when the additive was applied in the ratio 1:500 (vol percent).

The favorable ratios are in the range of 1/1500–1/500 (vol%).

How to store dispersant and depressor additives safely?

Antigel Dixon® can be stored in closed containers for an infinite period of time; however, there are some guidelines to follow in order to get the most out of this addition.

The suggested storage temperature ranges from -5 to +40 degrees Celsius. If the additive has been kept at a low temperature for an extended period of time, it should be combined before use.

The recommended dosage

1 liter of the additive per 1000-1500 l of fuel.

In the middle distillate Dixon® should be injected at a temperature of 10 ° C higher than the fuel cloud point.

Where is Dixon® used?

Winter diesel fuel contains a large amount of this ingredient. It is, nonetheless, effective for many fuels due to its wide range of activity.

There are three main areas of use:

- DT (90–20 percent) from 70 to 100 °C; DT (end boiling point 90 percent) from 17 to 25 °C; DT (end boiling point 90 percent) from 17 to 25 °C; DT (end boiling point 90 percent) from 17 to 25 °C; DT (end boiling point 90 percent) from 17 to 25 °C; DT (end boiling point 90 percent) from 17 to 25 °C; DT (end boiling point

- wide distillate fractions with a DT value of 90–20 percent from 100 to 120 °C and an end boiling point below 380 °C (ASTM D86 distillation); wide distillate fractions with a DT value of 90–20 percent from 100 to 120 °C and an end boiling point below 380 °C (ASTM D86 distillation);

- high-boiling distillates with end boiling point above 380 °С.

Antigel Dixon® parameters

| Name | Characteristics |

| Color | translucent colorless viscous liquid |

| Density at a temperature of 40 °C, kg/m3, no more than | 895 |

| Kinematic coefficient of viscosity at a temperature of 20 °C, cSt, not less than | 2,0 |

| Flash point, not less than | 62 °C |

| Boiling point, not less than | 180 °C |

| Pour point | -15 °C |

Working with dispersant and depressor additive DIXON®, please observe the following precautionary measures:

- avoid physical contact with it;

- using protective gloves and a mask is obligatory;

- for transportation in tanks the product is heated up to 60 °C and in case of skin contact may cause burns. If it occurred, it's necessary to wash the additive away with soap and a large amount of water. In case of eye contact they also should be rinsed by clear water immediately.

Keep spare containers closed at all times. Make certain that no water enters the product. Keep the additive away from flashpoints and open flames. Do not smoke in the vicinity of the containers. Empty containers may carry vapors that combine with air to generate an explosive mixture.

The product is only meant to be used for technical purposes!

Keep in mind that you own the key to your own safety.