Aplidium® — antiknock octane booster additive (EURO-5)

Aplidium® (from the Latin word "ecology") is the antiknock octane boosting additive developed in our own petrochemical laboratory.

More details

Drop® – сombustion catalyst

Combustion catalyst Drop® is a product created as a result of progressive technology.

More details

Ferrocene – antiknock additive

Ferrocene, being the representative of the sandwich compounds class, is known worldwide for its antiknock properties.

More details

N-Methylaniline

The main purpose of N-Methylaniline is to gain required proknock properties of gasoline during its production.

More details

DIXON complex - depressant-dispersant additive

To increase the filterability limit temperature (FLT) of the fuel, increase fluidity for storage and operation of fuels at low temperatures

More details

Cetane-boost additive 2-EHN "SIBERIA" 99.5%

For kerosene-containing, hydrotreated fuels with a low cetane number

More details

Antiwear (lubricating) additive “MOLECULE”

Necessary for hydrotreated fuels and kerosene fuels. Replaces oil injection into “dry” fuel, eliminates “carbon deposits” in the engine

More details

“DIXON-M” — depressant-rheological additive for oil and fuel oil

To improve the low-temperature characteristics of oils and heating oils

More details

Concentrated markers for petroleum products - protect your fuel from theft

Increasing of sales

Protection against forgery and in quality proceedings

Gaining consumer confidence

Universal for all petroleum products

Theft prevention

*Does not change the properties of the fuel and does not leave carbon deposits in the engine.

For whom?

1

Bunkering firms, fleets, farms, motor transport companies, mining companies, and coal mines are all examples of businesses.

- Anti-theft protection.

2

Petrol station, Oil refineries, Petroleum warehouses

- Creation of branded fuel.

- Bringing the fuel to the desired commercial color and shade.

Differences from competitors

Left 30gr/ton of normal dye, Right 3gr/ton of Sunshine dye

How the dye is supplied

Application method

The dye must first be dissolved in a small amount of fuel (10-20 liters), then poured into the storage tank and mixed in a closed loop using pumps before entering the storage tank.

The dosages of the dyes differ. Some paint the fuel with a saturated color, others with a paler one.

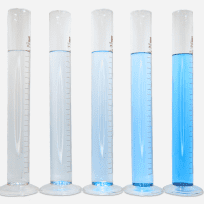

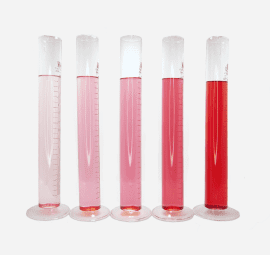

The concentrations shown below are: 1 g/t, 3 g/t, 5 g/t, 10 g/t, 20 g/t (from left to right, respectively).

The dosages of the dyes differ. Some paint the fuel with a saturated color, others with a paler one.

- 5 g per ton – average dosage

- 3 g per ton – minimum

The concentrations shown below are: 1 g/t, 3 g/t, 5 g/t, 10 g/t, 20 g/t (from left to right, respectively).